Description

Description:

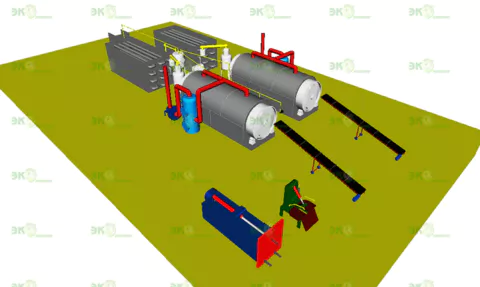

Pyrolysis plant B-20 (double reactors) is designed for complex recycling of hydrocarbon-containing waste such as:

-used tires

-rubber waste

-plastic waste (except PVC and PET)

-oil sludge, oily textile.

Technology:

Operation mode of the B-20 plant is batch(cyclical) type.

Plant capacity is 6 - 20 ton/batch, it depends on the type of raw material(waste), it's size and moisture. Two reactors working at the same time, so no need to people work at night.

The principle of equipment is based on technology of low-temperature pyrolysis with further condensation of pyrolysis gas. Pyrolysis gas goes throw condensers, cooling and became a liquid (fuel oil). Non-condensable gas can heat reactor, so no need for extra fuel. External fuel (wood, coal, etc.) is required only to heat the reactor to operating temperature. Plant B-20 use direct heating method.

Work cycle of B-20 plant (for used tires):

Stage

Carbon black discharging 2 hours

Loading raw material 2 hours

Heating reactors 2-3 hours

Pyrolysis 4-6 hours

Cooling down reactors*

Amount 10-12 hours

* Time of cooling down reactors takes at least 6(six) hours. It not include in the cycle because it does not require workers control.

Tire preparation for new batch(metal wire debeading and cutting) goes at the same time as heating reactor and pyrolysis process.

Technical parameters of B-20 plant:

Raw material capacity, ton/batch

6 - 20

Useful value of reactors (loading value), m3:

- for liquid, paste, bulk materials

24

- for other materials

52

Power consumption , kW/hour, 380V, 50 Hz

40

Working pressure, kPa

1-5

Reactors working temperature, 0C

380

Fuel consumption for heating reactors kg/batch:

- solid fuel (wood, coal,pellets)

400-500

- fuel oil

300

Workers /batch

4

Weight, ton

35

Area, m2

350

Delivery

three container 40ftHC, two container 20ft

Products:

The main product of B-20 plant is fuel oil (pyrolysis oil) which can be used directly as heating oil, and also can be a raw material for the production gasoline and diesel.

Other products are carbon black and metal (for tires). Without any modification carbon black can be used as raw material for production of fuel briquette, blackening pigment, asphalt modifier, fuel for coal-dust burners.

Metal can be sell directly to metal recycling factory.

Products yield for example:

fuel oil 35-45%

carbon black 30-35%

metal 15%

Specification B-20

Tire preparation set: Hydraulic still wire puller, Tire cutting machine, Conveyer 6m (x2).

Pyrolysis reactor set(x2): length 7000 mm, diameter 2200 mm, boiler steel thickness 15 mm.

Gas-heavy oil separator (x2)

Speed reducer(x2)

Pyrolysis gas burners (12 unit)

High pressure blowers (8 unit)

Gas pipe set (x2)

Compensator (x4)

Cooling pool and condensers pipe set (x2)

Light oil tank

Water sealing tank

Oil pump (x2)

Exhauster (x2)

Smoke pipes set (x2)

Water scrubber (x2)

Water pump (x3)

Control panel, sensors

Carbon black discharging system (x2)

Fittings, valves, screws, etc.

Spare parts.

Safety:

Equipment use safety valves, alarm system, etc. Our technology and experience guarantee of no fire and explosion accident.

Quality:

To providing the best quality we use european electric parts and russian heat-resistant steel. Also we directly control the quality of every important part of our machine.

Guarantee and Service:

For our customers we provide a professional service and engineer especially responsible for installation and technical support for all machine's life.

Guarantee for main parts is 12 months. The service life of main parts is at least 5 years.

Terms and conditions:

The price is FOB. Price includes full set of equipment, packaging, instructions and training employers.

Payment terms: negotiable.

- Tire recycling

Production Capacity:

Not informed

Delivery Timeframe:

Within 90 Days

Incoterms:

FOB - Free on Board

Packaging Details:

Not informed

More about

ECOHOLDING

0-10

Employees

200K - 500K

Sales volume (USD)

30%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

- Importer / Trading Company

Keywords

- Pyrolysis gasifier

Contact and location

-

Alex ********

-

+7 902********

-

Perm / PE | Russian Federation