Description

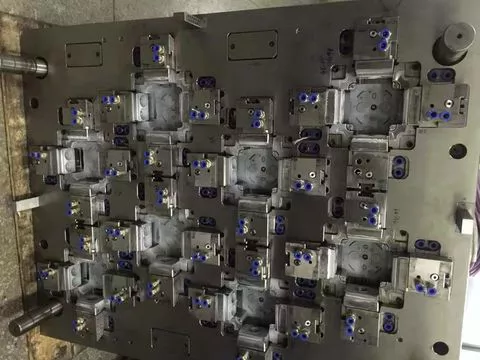

The various tools and products we use in our daily lives, from machine tool foundations and body housings to endonet screws, buttons and housings for various household appliances, are closely related to molds. The shape of the molds determines the shape of these products, and the quality and accuracy of the molds determine the quality of the products.

Due to the various products of different materials, appearance, specifications and uses, molds are divided into casting, forging, die casting, stamping and other non-plastic molds, as well as plastic molds. In recent years, with the rapid development of plastic industry, general and engineering plastics strength and precision, the application of plastic products is also expanding. For example, in many fields, such as household appliances, instruments, construction equipment, automotive industry, daily hardware, etc., the proportion of plastic products is increasing rapidly. Well-designed plastic parts can often replace many traditional metal parts. The trend towards plasticization of industrial and everyday products is on the rise. Plastic molds are short forms for combining molds for compression, extrusion, injection, blow molding and low foam molding.

By coordinating changes in convex, concave and auxiliary forming systems, a range of plastic parts of different shapes and sizes can be processed.

Mold design

Based on customer-provided 3D product data, with high quality, low cost, excellent technology and strong structure as the goal, according to customer standards to design mold structure data, and summarize on-site processing and commissioning to improve mold structure data.

Help customers adjust the thickness of their products to find the best balance between product quality and production costs.

Predict the appearance of the product of weld marks, gas marks, traps and other defects, predict and control them on the mold.

Predict product deformation to help customers improve product assembly structure, pre-design, avoid deformation.

Proper lying of the glue and cooling system provides the best process results and the most economical investment.

Provide optimized production process parameters to help customers solve product injection molding production problems.

Participate in product design, provide support to customers, carry out feasibility analysis of products and mold structure, solve problem points early, save time and cost of mold design and processing, improve quality.

Mold production

The engineering department determines the external requirements of the mold cavity, structural accuracy requirements, spare parts and manufacturing standards, then PE engineers produce process sheets and process control tables, and determines the technical department to follow up, improve and monitor the difficulties, key points and error-prone problems of the entire mold processing. Our team is a highly qualified team that specializes in manufacturing high demand and difficult molds. Gud Mold's employment and compensation systems give them new technical capabilities and a greater sense of responsibility.

"Take action now, deal with it now" is our mantra and inertia.

Mold making: NC layered processing combinations are used to detect model defects through photographic scanning measurement and design comparison.

CNC processing: all 2D parts of the mold base and blade are processed with three-axis CNC, and all 3D parts are quenched with five-axis high-speed CNC processing to ensure processing accuracy and mold quality.

Research and commissioning: independently set up a debugging team with more than five years of experience, focusing on debugging.

Product production Using imported all-electric equipment vertical, horizontal and two-color molding, Gud Mould has a wealth of manufacturing experience, suitable for highlights, special engineering materials, transparent, electroplating products, molding technology in the forefront of the injection molding industry. The continuous application of automation equipment greatly improves efficiency and ensures the steady adoption of all-electric injection molding equipment and automated production processes, different types of monochrome and multi-color molding machine equipment from 30 tons to 1300 tons, continuous improvement, excellence, full participation in improving quality, efficiency and cost, and continuously improve customer satisfaction,

And strive to become a leader in the becom industry! Gud Mould has an independent engineering, quality control and injection molding department to ensure the quality of the injection molding products and make the production process more scientific and stable. We understand the performance of PP, POM, PVC, PC, PPS, PBT, PA46, PA6, injection molding process, mold technology.

We are proficient in hot oil machine, oil pressure pumping core, hot runner, casting and other technologies.

Assembly To provide customers with large-scale assembly and manufacturing business, including projects, process technology, production, manufacturing, warehouse, quality and other integrated assembly and manufacturing services, Gud mold has a modern dust-free workshop, the use of 6S on-site production management, for each team to implement target management, and real-time tracking of the entire production process. We focus on operator skills training and evaluation, the implementation of 3P independent inspection, strict control of product traceability, comprehensive assurance of the assembly process quality control, to ensure customer product quality, to provide customers with the leanest assembly manufacturing.

- Automotive molds

- medical molds

- plastic molds

- injection molds

Production Capacity:

Not informed

Delivery Timeframe:

Not informed

Incoterms:

Not informedPackaging Details:

Not informed

More about

Gud Mould Industry Limited

50-100

Employees

10M - 50M

Sales volume (USD)

40%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- Plastic Molding

- INjection Moulding

- Automotive Molding

- Medical Molding

- Die Casting Mould

Contact and location

-

Jackie ********

-

+86 15********

-

Dongguan / Guangdong | China