Description

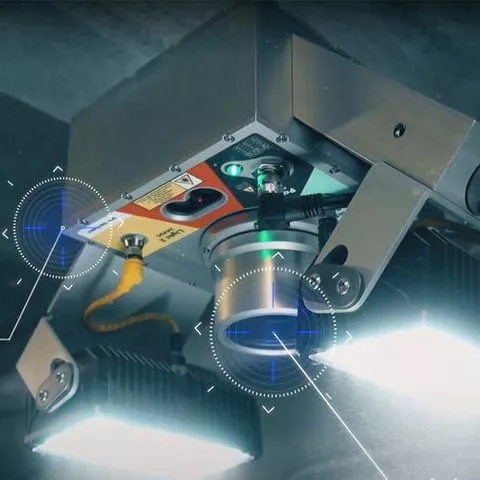

Analyze and monitor bulk material directly on the running conveyor belt 24/7 in real time.

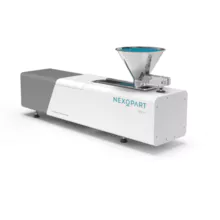

Increase your productivity with the NEXOPART INLINE

The NEXOPART INLINE allows you to monitor, document and analyze non-solidified bulk solids very quickly and easily at the unloading station or on the running conveyor belt. The analysis process takes place continuously 24/7 and in real time. You therefore digitize your very first process steps and optimize your efficiency right from the start.

Versatile analysis possibilities

The use of the NEXOPART INLINE enables:

•Analysis of particle shape and size

•Detection of color differences (Color-ID)

•Continuous monitoring

•Automated process control

The data can be sent directly to an alarm/ PLC/ process. This way you optimize the efficiency of your process and create additional capacities.

- Laboratory equipment

- Dynamic image analysis

Production Capacity:

Not informed

Delivery Timeframe:

Not informed

Incoterms:

Not informedPackaging Details:

Not informed

More about

NEXOPART® GmbH & Co. KG

Not informed

Not informed

Not informed

Year

Established

Business type

- Industry / Manufacturer

Keywords

- Sample division

- sample analysis

- Test sieve shakers

- Test sieves

- Dynamic image analysis

Contact and location

-

Vanessa ********

-

+49 25********

-

Oelde / Nordrhein-Westfalen | Germany