QBF-SINO WALL has been committed to the development of the Sidewall Conveyor Belt system and lead the latest developments in steep angle conveying using the Sidewall Conveyor Belt System in China based on decade years working experiences with customer in the global market.

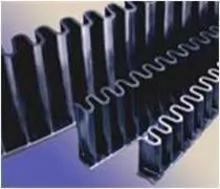

For base belt, we also carefully select the correct rubber compounds for the sidewalls & cleats in terms of strength, flexibility and abrasion resistance. These compounds can be modified to suit certain specific requirements, such as where material is hot nor where there is a risk of fire.

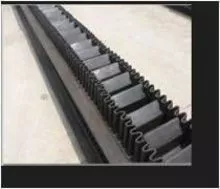

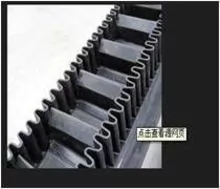

The sidewalls and cleats are designed in accordance with the function they are required to carry out. The purpose of the sidewalls is to retain its load at the edges of the pocket yet being extremely flexible in order to negotiate the bend points on this type of conveyor. The cleats are required to support the load and these are often individually moulded to a specific design so that they retain their shape even when operating vertically with high density materials.

The sidewalls and cleats are attached to the base belt as a result of a special hot vulcanizing process. This gives the higher adhesion values and can be an advantage when material has high temperature.

As a result of manufacturing within China, we are able to offer a high quality product at a competitive price level follow the export standard , and this also provides a quick response service when required.

Anna ********

+86 53********

qingdao / | China