Description

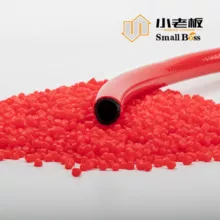

PVC (Polyvinyl Chloride) shoe granules, also known as PVC compounds, are a versatile and widely used material in the footwear industry. These granules are manufactured by blending PVC resin with various additives, including plasticizers, stabilizers, fillers, and colorants, to create a compound with specific properties tailored to different shoe manufacturing requirements.

One of the primary advantages of PVC shoe granules is their excellent flexibility and durability. Plasticizers are added to the PVC resin to enhance its flexibility, making it suitable for a wide range of shoe styles, from casual sneakers to formal dress shoes. The addition of stabilizers ensures that the material remains stable under various environmental conditions, preventing degradation and maintaining its physical properties over time. Fillers, such as calcium carbonate, are incorporated to improve the strength and hardness of the granules, while colorants are used to achieve the desired aesthetic appearance.

Another significant benefit of PVC shoe granules is their cost - effectiveness. PVC is a relatively inexpensive raw material, and the manufacturing process for producing PVC shoe granules is relatively simple and efficient. This makes PVC shoe granules an attractive option for footwear manufacturers looking to produce high - quality shoes at a competitive price. Additionally, PVC shoe granules can be easily recycled, reducing waste and contributing to a more sustainable manufacturing process.

The production of PVC shoe granules involves several steps. First, the PVC resin is mixed with the appropriate additives in a high - speed mixer. The mixture is then heated and extruded through a die to form continuous strands, which are cooled and cut into small granules. These granules are then ready for use in the shoe manufacturing process.

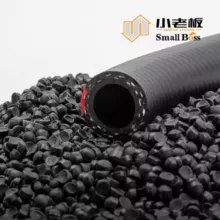

PVC shoe granules are used in a variety of shoe manufacturing techniques, including injection molding, blow molding, and calendering. In injection molding, the PVC granules are melted and injected into a mold to form the shoe sole or upper. Blow molding is used to create hollow shoe components, such as air - filled soles, while calendering involves rolling the PVC compound into a thin sheet, which can be used to make shoe linings or other components.

In addition to their use in traditional footwear, PVC shoe granules are also finding applications in the sports and outdoor footwear market. Their excellent water resistance, abrasion resistance, and slip resistance make them ideal for use in shoes designed for activities such as hiking, running, and water sports.

However, it is important to note that the use of PVC in the footwear industry has raised some environmental concerns. PVC contains phthalates, which are plasticizers that have been linked to health problems in humans and animals. As a result, many footwear manufacturers are now looking for alternative materials or reducing the use of phthalates in their PVC shoe granules.

In conclusion, PVC shoe granules are a versatile and cost - effective material that plays a crucial role in the footwear industry. Their excellent flexibility, durability, and ease of processing make them suitable for a wide range of shoe styles and manufacturing techniques. While environmental concerns remain, ongoing research and development are focused on finding more sustainable alternatives and improving the environmental performance of PVC shoe granules.

- PVC granules

- PVC compounds

- PVC

- PVC material

- PVC for shoes

- PVC for fittings

Production Capacity:

20000

Delivery Timeframe:

Within 30 Days

Incoterms:

CFR - Cost and Freight

CIF - Cost, Insurance and Freight

CIP - Carriage and Insurance Paid to

CPT - Carriage Paid to

DAF - Delivered At Frontier

EXW - Ex Works

FOB - Free on Board

Packaging Details:

25kg per bag 1 ton per bag

More about

Tongxiang Small Boss Special Plastic Products Co.,ltd

200-500

Employees

10M - 50M

Sales volume (USD)

70%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

- Other

Keywords

- PVC granules

- PVC compounds

- PVC

- PVC material

- PVC for shoes

- PVC for fittings Ver Mais

Contact and location

-

Abby ********

-

+86 1********

-

Tongxiang / Zhejiang | China